by Vihab

PST:s dotterbolag Vihab har vibrationsteknik som specialitet. Vare sig det gäller att dosera, transportera, sikta, lossa eller packa material, så har Vihab, med mer än 50 års erfarenhet av vibrationsteknik, lösningen på era problem.

Vi ställer självklart upp med den kringutrustning som behövs för en nyckelfärdig anläggning. Genom vårt breda kontaktnät av specialister inom såväl mekanik som elektronik är vi flexibla och kan anpassa oss till varje enskilt projekts specifika krav.

Rens, avloppsslam, sediment, bioslam, kalkslam

Karbonider, magnetit, natriumsulfat, aluminiumfluorid, titandioxid, stendamm

Pulver, kalkgrus, rejekt från pulpers, metallspån, cement, sand, rötrester, salt, stärkelse, järnoxid, petrokoks, aktivt kol, glasfiber

Hö, halm, spannmål, gryn, korn, hönsfoder

Karbonider, magnetit, natriumsulfat, aluminiumfluorid, titandioxid, stendamm

Flis, sågspån, pellets, bark, kutterspån, fiberslam, aska, briketter, träkol, pappersfibrer, pinnflis, strimlat papper

Grönsaker, glas, matavfall, lampor/lysrör

Granulat, kapsyler

Frakt, emballage och moms tillkommer på priserna. Vid faktura gäller 30 dagar netto efter sedvanlig kreditprövning. Annars tillämpas förskottsbetalning. Vid försenad betalning utgår dröjsmålsränta. Levererade varor förblir Vihabs egendom till full likvid erlagts.

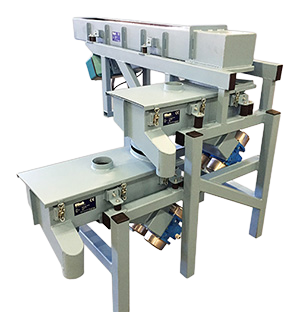

Vihab vibrationssiktar med ett, eller flera siktdäck är avsedda för fraktionering av pulver- och kornformigt material. De används inom industri av skiftande slag såsom gjuterier, legeringsverk, kemisk-teknisk industri, trä-fiber-cellulosaindustri, livsmedels- och konservindustri, energi- och värmeverk. Mångsidigheten hos Vihabsiktarna gör dem lämpliga för såväl torr- som våtsiktning, förtjockning och avvattning, kontrollsiktning, dammavskiljning m.m.

Vihabs matningsrännor används för de flesta typer av material ,och inom industrier av skiftande slag; exempelvis gjuterier, gruvor, legeringsverk, kemisk-teknisk industri, och livsmedelsindustri. Ränntrågen utföres som standard i stålplåt, men kan även erhållas i rostfritt eller syrafast utförande, eller med inlägg av slitplåt, slitgummi, eller konstfibermaterial.

Rännorna är försedda med gummidämpare eller spiralfjädrar för uppställning. Vid extrema belastningsfall används spiralfjädrar med inbyggda gummidämpare.

Med ett långslagigt, lågvarvigt excenterelement och länkarmar lagrade i mjuka gummibussningar åstadkommer vi en skonsam transport, både för material och omgivning. Ljudnivån hamnar under 70 dB (A).

Rännorna är försedda med gummidämpare eller spiralfjädrar för uppställning. Vid extrema belastningsfall används spiralfjädrar med inbyggda gummidämpare.

Specialrännor med siktinsatser, matningsrör med cirkulärt eller rektangulärt tvärsnitt, vätske kylning, eluppvärmning etc. offereras på begäran.

Vi har ett stort sortiment av vibratorer såsom motorvibratorer, magnetvibratorer, tryckluftvibratorer och hydrauldrivna vibratorer.

Rationell uppslagning ger betydande tidsvinster, och gör arbetet lättare och billigare. Vihab:s gjuteriurslagare HS har med framgång använts sedan länge. Vi kan även leverera transporterande urslagare samt kompletta urslagare med transportrännor för borttransportering av formsanden.

Vihab:s smådelsmatare för orientering och utmatning av detaljer används vid förpackning och montering av komponenter såsom skruvar, muttrar, brickor, kugghjul etc.

Dosermataren består av ett ränntråg fast monterat på ett magnetdrivdon. Oavsett vilken kapacitet ni önskar så finns en Vihab dosermatare som passar era behov.

Ränntrågets utformning anpassas efter era behov avseende mått, material och eventuell inkapsling. Rännan kan också förses med siktinsats om ni så önskar.

Tomrum kostar pengar. Varför betala för onödigt skrymmande emballage?

Med Vihab:s vibrationsbord på fyllningsstationen packas materialet till optimal packningsgrad; och emballage- och fraktkostnaderna hålls till ett minimum. Säckar, storsäckar, kartonger, fat mm med pulver- eller kornformiga material vibreras med fördel på vibrationsbord typ GB, där vibrationerna alstras av en motorvibrator.

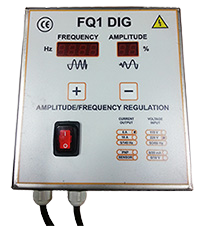

En amplitudgivare monteras på den vibrerande utrustningen och ansluts till centralenheten.

Från larmutgången dras signalkabel till önskad plats, vanligen kontrollrummet varifrån processen styrs.

Centralenheten kalibreras för den amplitud som utrustningen normalt arbetar med.

Om driften störs av att t.ex. kletigt material bakar på en ränna eller en sikt och kapaciteten därmed sjunker så ger övervaknings-utrustningen larmsignal.

Skulle någon väsentlig del av den vibrerande utrustningen lossna med följd att amplituden ökar utlöses larm även då.

Tyristorstyrdon för alla typer och storlekar av magnetvibratorer.

Styrdonen finns för inbyggnad eller som kapslade don. Alla styrdonen är klara för fjärrstyrning.

Vihab kan erbjuda en rad lösningar såsom siktlinjer för glaskross, och spiralmatare.

Har du frågor om någon av våra produkter? Vi berättar gärna hur hur vi kan effektivisera din materialtransport. Har du en idé som kräver speciallösningar? Fyll i formuläret eller hör av dig direkt till Michael Norlanders på +46 (0)706 645 612 eller michael@vihab.se.